ホース用プラスチッククランプは、プラスチックのさまざまな機能と組み合わされた強力なメッシュを備えた新しいタイプの構造ファスナーであり、外観の調整によって作用力を変換するために正確な歯のタイプの構造でうまく設計されていますを使用します。 プラスチック製のホースクリップは、ネジやナット、金属製のホースクランプ、ロープなどの従来の留め具に代わることができる、接続、固定、およびシーリングチューブ用の一般的に使用される新しいタイプのアクセサリです。そしてまた容易な固定、強い力、よいシーリング、便利な分解、リサイクルおよび高いコストパフォーマンスの利点と。

ルンゼ販売のための高品質のプラスチックホースクランプを提供し、OEM堅牢なホースクランプは完全にサポートされています。

Model No. (New) | Material | Color | Adapted Diameter (mm) | Product Width (mm) |

1000000001 | POM | White | 3.8-4.3 | 22 |

1000000004 | 4.3-4.8 | 22 | ||

1000000003 | 4.9-5.4 | 22 | ||

1000000024 | 5.5-6.0 | 22 | ||

1000000010 | 6.0-6.5 | 22 | ||

1000000002 | 6.5-7.0 | 23 | ||

1000000013 | 7.0-7.5 | 24 | ||

1000000005 | 7.5-8.0 | 24 | ||

1000000006 | 8.0-8.5 | 26 | ||

1000000018 | 8.6-9.1 | 26 | ||

1000000012 | 9.1-9.6 | 26 | ||

1000000007 | 9.6-10.2 | 25 | ||

1000000008 | 10.2-10.7 | 26 | ||

1000000015 | 10.7-11.2 | 25 | ||

1000000016 | 11.1-11.6 | 25 | ||

1000000009 | 11.6-12.1 | 24 | ||

1000000011 | 12.0-12.5 | 26 | ||

1000000017 | 12.6-13.1 | 28 | ||

1000000023 | 12.3-14.0 | 25 | ||

1000000014 | 13.1-13.6 | 33 | ||

1000000022 | 13.7-14.2 | 28 | ||

1000000025 | 14.2-14.7 | 27 | ||

1000000019 | 14.7-15.2 | 27 | ||

1000000020 | 15.2-15.7 | 27 | ||

1000000053 | 15.2-17 | 32 | ||

1000000055 | 21.5-23.5 | 40 | ||

| 1000000021 | 24.3-26.1 | 48 | ||

| 1000000026 | 35.5-37.5 | 51 |

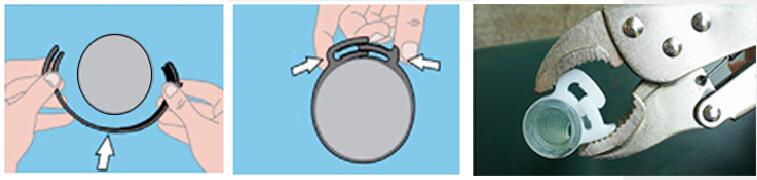

a. Connecting your tube fully into a connector

b. Use vernier calipers to measure the total diameter where you want to fix after tubing connected with connector (see above figure)

c. Choose a suitable model according to above-adapted Diameter listings

d. Slip the hose clamp until reaching the connector, then close the gear until it is tightly fastened

Clamp the outermost tooth with a wire-cutter (please don't clamp left and right tooth together), move flatly and gently as the tooth slot, fleetly twist it with small angle(upper and nether tooth misplaced), then it will be loosened, Please note keep small angle when twisting to ensure the tooth non-deformed when misplaced it is reusable.

Solutions for Common Problems

1. Checking the fastening effect

Rotate the hose clamp manually to ensure it is tightly fastened with no blind side, good sealing and a smooth fastening surface.

2. Leakage and shed after pressured

a. Leakage after pressed includes many caused such as hose clamp with insufficient force, the diameter of the tube is far more than the outer diameter of the connector, a tube with insufficient flexibility, etc.

b. Shed after pressured includes two causes: one is surpassing limit pressure of hose clamp with inner tooth prop up the outer tooth, multi-tooth lose common mesh (only rely on the main tooth); another is the friction force between tube shed off (head part is still fastened). The solution is to choose the right specification or simultaneously use two pieces of hose clamps (head part should be placed at two places, or it will be hard to disassemble)